The stick-and-rudder skill deficiencies in today’s pilots didn’t start today. It began years ago when they were learning how to fly. Fixing it will require a journey into the past. It’s time to get back to basics, and you won’t cover all the bases unless spin training is a central part of the mix. Read more →

Tag: flying

Aviation Scholarships

Okay, so you want to pursue flight training but the funds just aren’t there. Wouldn’t it be great if someone appeared out of thin air with the money you need to achieve your goal? It’s not as far-fetched as you might think… Read more →

The Good Life

To me, flying is The Good Life, even when you’re not in the air. Here’s a video that says it better than I ever could. Read more →

Constant Speed Propeller Maintenance

Physical failure of a prop blade or hub in flight is far more likely to kill you than an engine failure. So why do many pilots ignore the relatively infrequent maintenance needed by their constant-speed propeller? Read more →

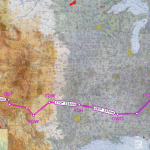

Low and Slow

Flying’s always an adventure — especially when it’s a coast-to-coast trip in a light aircraft! Read more →

Affordable Flying

Fewer and fewer non-professional pilots can afford to stay in the cockpit anymore, but there are quite a few ways to reduce the cost of flying if you’re creative about it. Here are a few ideas to get you started. Read more →

Married!

I explain the lack of updates on the site, along with current news from the aviation sector and my personal life. Read more →

A Day at Medfly

A photographic tour of a day of flying at the California Medfly eradication program — one of my many day jobs. Read more →

US Airways 1549 Damage Photos

Fascinating damage photos taken during the salvage of US Airways Flight 1549 illustrate just how tough aircraft are built. Read more →

Kristi’s Cub Flight

An account (with photos) of a sunset flight down the coast in a 1943 Piper J-3 Cub. Read more →