Every aviator has their soapbox issues, and when it comes to maintenance, my top two are constant-speed propellers and aircraft tires. I may touch on the former in a future article, but for now let’s focus on the latter.

Tires are one of the most vitally important — yet frequently ignored — parts of an aircraft. It’s easy to see why: they’re relatively simple elements which work day in and day out without problem, and as such are taken for granted. In addition, some of the typical pilot’s attitude toward tires is transferred from the way they treat their automotive counterparts. Be honest, how often do you inspect your car’s tires? When was the last time you checked the pressure on all four wheels? I’m about as anal as a person gets when it comes to car maintenance and upkeep, and I might check the tires once every couple of months at best.

In a light GA aircraft, tire failure on the takeoff or landing roll can lead to loss of directional control, runway excursion, and/or a ground loop. These things are unlikely to be fatal but are frequently embarrassing and inconvenient as they’ll shut down the runway for a while. I’ve had several of those in my career. Ironically, it always seems to happen during a student’s softest, smoothest 3-point landing in the Decathlon. Well, almost always.

I once lost a tire — literally — while taxiing a Pitts S-2C. I had stopped for cheap fuel in Limon, Colorado, a paved but little-used strip on the edge of a small town near the Nebraska border. After a great landing in a 25 knot crosswind, I refueled and started to back-taxi on the runway when the left main tire slowly deflated. I shut down and opened the canopy, but as soon as my feet came off the brakes, the airplane weathervaned into the wind, taking the tire right off the rim as it pivoted. Now I couldn’t even move the plane.

Oh, and did I mention the sun was setting soon and the runway had lights? Suddenly the flat tire was less important than ensuring some wayward pilot didn’t attempt a night landing with my disabled, unlighted biplane sitting on the runway.

Light aircraft flats are more often caused by the failure of the tube than the tire itself. The Pitts incident taught me the value not only of proper tire inflation, but also of alighting at airports with maintenance services when flying cross-country. Making that trip today, I’d at least carry a spare tube.

Of course, that won’t always save the day. I once had to rescue a friend from Death Valley when his underinflated aircraft tires melted into the tarmac on a 120+ degree day. Tire condition can be difficult to judge on fixed-gear aircraft on account of the fairings which often hide 90% of the rubber from view.

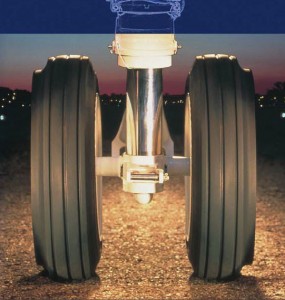

In turbine aircraft, improperly inflated tires are more likely to lead to expensive damage, if not outright catastrophic consequences, due to the higher speeds and heavier weights of those aircraft. There’s simply a lot more kinetic energy for the tires to absorb. This is why turbine aircraft tires are stronger and more advanced than those found in their lighter brethren. It also explains why those tires are filled with nitrogen instead of air. Nitrogen doesn’t expand at altitude the way air does. It has a low moisture content so it doesn’t freeze, and it will not support combustion.

The FAA recently issued Safety Alert for Operators (SAFO) bulletin 11001, “The Importance of Properly Inflated Aircraft Tires”, which notes:

Research has shown that transport-category airplanes can lose as much as five percent of tire pressure per day under typical operations. At a pressure rate loss of five percent per day, it would only take a few days before they require servicing.

Tires not serviced within an acceptable range may require tire replacement due to under inflation limitations specified in the maintenance manual. Additionally, servicing of underinflated tires without proper protection such as a tire screen or other protective devices may cause damage to the aircraft or injury to the individual servicing an underinflated tire.

The FAA’s not alone in their crusade to get us to pay more attention to our tires. Last week, Gulfstream reviewed tire safety “best practices” in their weekly Breakfast Minutes publication. It referenced the Goodyear Aircraft Tire Care and Maintenance publication. It’s an excellent read.

A bit of research revealed that tire failure has caused a variety of high-profile jet accidents, including Air France flight 4590, Nigeria Airways flight 2120, Mexicana flight 940, and most recently, the 2008 crash of a Lear 60 in South Carolina.

That last accident was cited in their SAFO bulletin. In fact, the FAA recently issued an Airworthiness Directive for the Lear 60 which requires a tire pressure check no less than 96 hours before any flight.

Obviously it’s not possible to prevent every instance of tire failure, but we can skew the odds in our favor by paying more attention to them. That means checking the tire pressure at appropriate intervals. Mounted tube-less aircraft tires lose significant pressure every single day, and underinflated tires cannot necessarily be detected by simply looking at them. If nothing else, proper inflation leads to longer tire life and better ability to survive FOD damage should it be encountered. Remember too that the landing and takeoff distances listed in the Aircraft Flight Manual are predicated on proper tire inflation!

To show the importance of proper tire pressure, consider that as a tire leaves the deflected area (aka the ground) as it turns, it attempts to return to its normal shape. Due to centrifugal force and inertia, the tread surface doesn’t stop at its normal periphery but overshoots, thus distorting the tire from its natural shape. This is called a traction wave. Assuming the tire is turning at 250 mph:

At this speed, it takes only 1/800 of a second to travel 1/2 the length of the footprint (CX). In that same time, the tread surface must move radially outward 1.9 inches. This means an average radial acceleration of 200,000 ft./sec./sec. That’s over 6,000 G’s! This means the tread is going through 12,000 to 16,000 oscillations per minute.

Tires are designed to withstand traction waves… but only while inflated to the appropriate pressure. Under or overinflation will magnify the effect of traction waves. Suddenly the AFM recommendation on tire pressure seems pretty important, doesn’t it?

Speaking of the AFM, the landing gear may have other limitations which must be observed. In 2007, I witnessed first-hand what happens when those limitations are exceeded.

Whatever you call them — tyres, hides, skins, rolling stock, stickers — aircraft tires are certainly one of the most highly-stressed yet least respected parts of an aircraft. Next time you fly, think closely about the punishment they take and whether you’re sure those babies are truly airworthy.

http://www.flyingsummers.com/2006/02/fame/

I have now had three flat tires in my Diamondstar. I switched tubes from Goodyear to Michelin after the last one and I have not had a problem since. I also put a timer in the G1000 to check the pressure every 15hrs of flying, or something like that. It would be a lot easier without the fairings and I would probably do it every flight. Or close.

A fellow Diamondstar pilot is using some wireless tire pressure monitor which seems like witchcraft. I am waiting for the longterm review.

Tire pressure monitors are available on $10,000 cars nowadays. You’d think they’d have them on a $400,000 aircraft, eh? As always, it comes down to weight and complexity — something not nearly so vital in a car.

I assume the Michelins you’re talking about are the AirStop tubes? I’ve had excellent experience with those as well. They’ll still lose pressure, but not nearly as quickly as a typical tube.

Correct, the AirStop. And I took the extreme step of buying a jack, spare tube, pump and carrying everything I need to change a tire. I even jacked up the plane at my tie-down to try everything out. I do not like the idea of messing with the brakes and other things necessary to do the work, but I occasionally land at little strips where it could make the difference between being a hazard to someone else.

I think someone could make a product like a skateboard which could get you to a safer place to wait, but we couldn’t figure out a way not to do the jacking system. Airplanes seem so fragile on the ground. Do you think you could have passengers sit on the far wing and seesaw the flat off the ground that way?

It might work, but I wouldn’t recommend it. The wing and it’s attach points were not designed with that kind of stress in mind. I don’t know that it would dfinitively hurt the wing, but if it did, you might not be able to see the damage inside the wing root. Probably not worth it. At the very least, I’d talk to Diamond to see what they say about it.

No, not a chance I am going to try it, I was just curious.

http://www.amazon.com/Show-Chrome-WIRELESS-PRESSURE-MONITOR/dp/B001VDUBHW

See? $170 and you never wonder again.

I wonder if those would be ok on an aircraft. It was designed for a motorcycle, and despite the metallic valve stems, I’d be worried about the effect of the extra weight from that pressure sensor/cap during the instant spin-up from zero to 70 mph during touchdown.

Certainly great to know the tire pressure, though. Ironically, even relatively large jets like the Gulfstream IV don’t have any built-in tire pressure monitoring. The new 650 will have it, however.

Great blog. Keep it coming!

Very timely info. Just had a flat this last week on my 2006 DA-40. I expected FOD, but close investigation shows a failed tube. Tube was date stamped 2006! So in 6 annuals, and at least 2 full sets of new tires and no one thought to change tubes? (I admit it never even occured to me to ask, I just assumed new tire meant new tube!) I saw this too late to get Michelin tubes, but now I am worried. I am tempted to raise the PSI from the recommended 33 to perhaps 40? (A&P tells me he is instructed to raise PSI on all “Club” planes +10 PSI.) I also was told exact same tire tube combo on other planes is 52 and 65 PSI in the POH (Cirrus and Cessna 182). Why is the DS so much lower? Any danger going a little higher than the POH? I promise to crawl out of the wreckage and let some air out of the tires if the insurance man comes. Thank you Colin on your helpful information.

No A&P who wants to keep his ticket would design maintenance practices that are different than the manufacturers data. The tire is probably capable of a pressure higher than the recommended pressure, but you have to keep in mind that the tire itself is part of the landing gear system. The landing gear designer is counting on a certain amount of tire deflection as part of the overall method of absorbing the shock of landing. Use the recommended pressure. Also…if you ever put on a new tire…put in a new tube. A brand new tire will “grow” a small amount after it is installed and inflated. The tube grows with it. If you put an already stretched-out tube into a new tire it will be a little too big. The tube can get a fold in the rubber, and it will crack at that fold. You’ll install that tire only to come out the next day to find a flat tire.

The recommended pressure is, of course, ideal. However it is sometimes impractical to fill tires using the methodology recommended by the manufacturer. I’ve seen tire pressure recommendations which were predicated on having no weight on the tires at the time of measurement. How ridiculous is that?

Even when that’s not the case, there’s a big difference between hot and cold tires or empty weight vs. max gross on the landing gear at the time of measurement. In other words, there many are variables in play. Is the ramp slanted? Has the tire pressure gauge been calibrated?

There are many reasons I’d rather have the pressure a little high than a little low. A flat tire when the plane is sitting on the ramp is one thing. What I really want to avoid is a tire failure during takeoff or landing, and that’s much more likely with low pressure. In addition, high tire pressure will naturally correct toward the recommended value as time passes, whereas low pressure only gets further and further from the ideal value.

You make a good case….as long as the overinflation is done with a modicum of judgement. Maybe 10% over would be a good starting point.

Another thing to pay attention to when comparing the wheel/tire combinations between different aircraft is the tire ply rating. A Cessna 150 uses a 6.00-6 wheel/tire and so does a 205. The 150 uses a 4 ply tire and the 205 requires an 8 ply tire. The max inflation pressure for the 4 ply is somewhere around 55 psi and around 85 psi for the 8 ply tire. The caution would be to not assume that because one airplane with a particular size tire has a relatively high tire pressure, that it’d be OK to run that pressure on another type of airplane with the same tire size.

I may be the only GIV pilot that keeps a tire pressure gauge in his suitcase. (it fits handily inside a shoe when packing for a trip)

Great idea, Art! We should all be doing that, especially with planes like the G-IV which are often on the road for weeks or even months at a time before returning home.

Have you ever lost a tire on a Gulfstream? Every time I preflight the main gear on one, I think about how destructive a tire failure could be, particularly in La Paz or other location where landing speeds exceed 200 mph. That’s s lot of kinetic energy!

Hello All,

This blog entry caught my attention because I am a business development manager for a company called Crane Aerospace. A few years ago Crane developed an aircraft tire pressure system which is called SmartStem. SmartStem is the only passive, wireless tire pressure sensor available for business jets, regional and commerical aircraft. We are in the process of certifying SmartStem on additional aircraft however we currently hold certification and PMA for the LearJet 60, LearJet 40/45, DHC-8 100/200/300/400, Cessna Citation X and Sovereign, FalconJet 50, Boeing 747-400, Boeing 777 and Boeing 787. We have been standard equipment on 777 since 2008 and on new production 787s since production start in 2009. We are working with additional OEMs to offer certifications on Challengers, Global Express, CRJs, the Gulfstream jet family, Phenom 100/300 and ERJs. For more information on the SmartStem system please visit our website:

http://www.craneae.com/Products/Sensing/SmartStem.aspx

I hope this will help some of you! Thank you!

Kate Gregory

Thanks for the information, Kate! I know the Gulfstream G650 was designed from the ground up with a TPMS, and most news jets will probably have it going forward, but there are still a lot of aircraft without this capability.

Is Crane (or anyone else you’re aware of) considering a TPMS system for the piston-powered GA fleet? Checking tires on those aircraft is often neglected because fixed-gear aircraft typically have tight fairings around the landing gear which are time consuming to remove.

# “Nitrogen doesn’t expand at altitude the way air does.”

Dry nitrogen behaves exactly as does dry air with respect to altitude – see Boyle’s Law – but that is irrelevant when the nitrogen (or air) is contained within a tire, because its volume is constant. The reason for using nitrogen is that its diffusion rate through a tire is less than that of air, so the tire maintains pressure over a longer period when filled with nitrogen.

Dear Dr. Mant: This was my question exactly. I was wondering whether pure nitrogen obeyed a different set of gas laws than the normal atmospheric gases (78% nitrogen, 21% oxygen, 0.9% argon, 0.03% carbon dioxide and traces of others). Thank you for addressing this issue.

AND the nitrogen does not oxydize the inner wall of the tire or tube. Martin: The reason some lighter aircrafts have a “,,low” tire-pressure is the same as with old Harleys with rigid rear frame: Shock absorbing, kind of spring so to say… Greets, Gerard retired checker as balancer of Thunderstreak and Starfighter landing wheels and gear.